1 off cnc machining

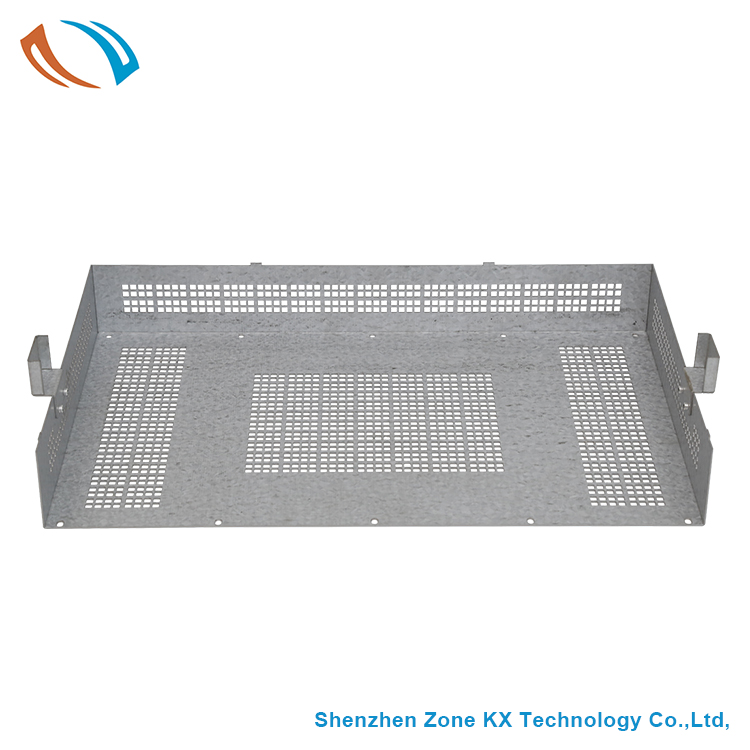

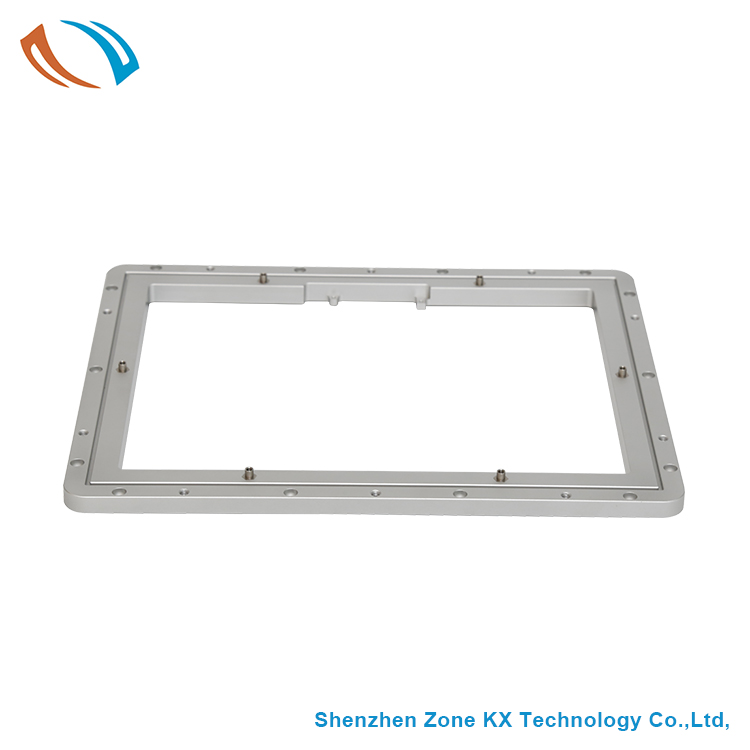

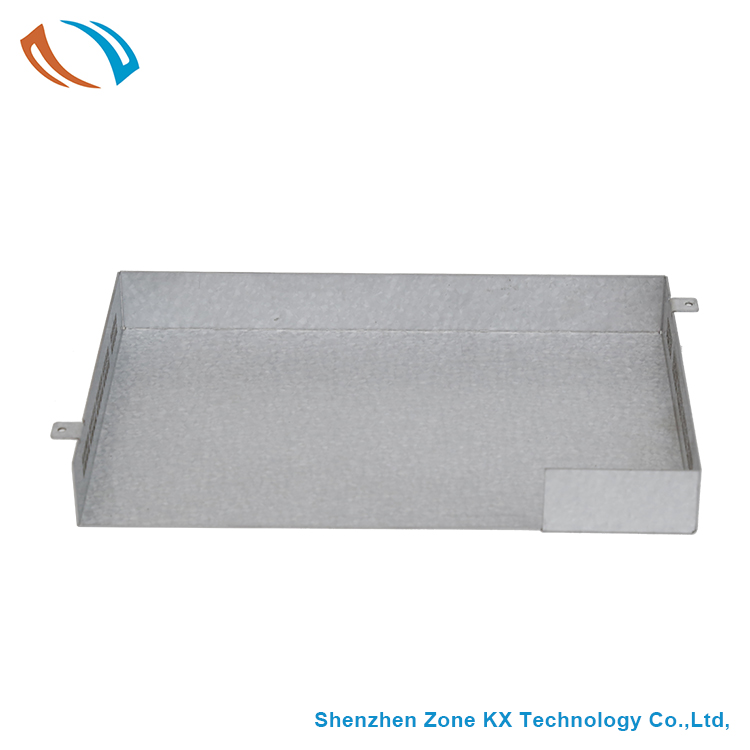

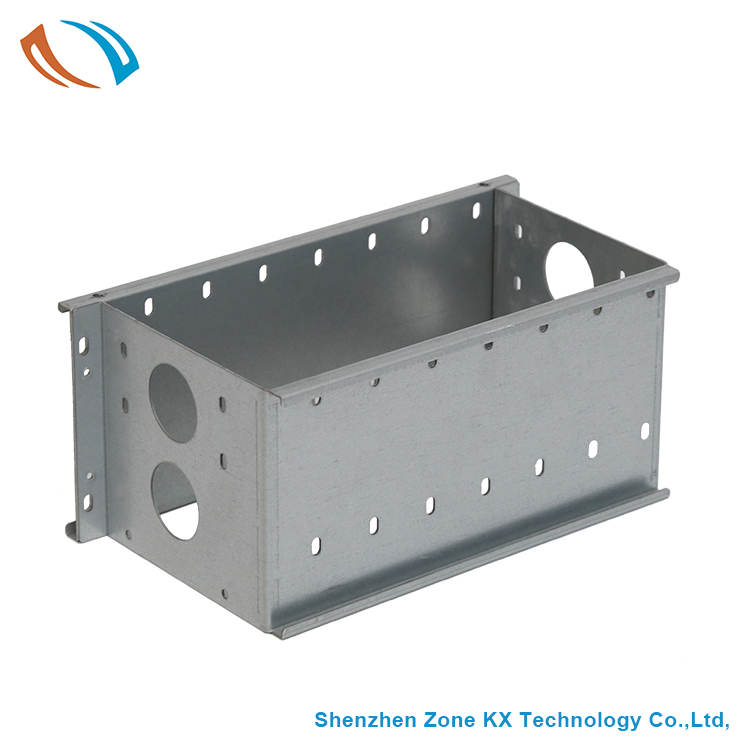

Product Name: CNC Machining ProductProduct Type: Mechanical Component

Production Materials: Various Metals (Aluminum, Steel, Titanium, etc.)

Production Process: CNC Machining

Dimension Tolerance: +/- 0.01mm

Surface Finish: Smooth (Ra < 0.8um)

Product Strength: High

Product Accuracy: Precise

Production Capacity: Customized according to customer requirements

Lead Time: Variable, depending on product complexity and quantity

Quality Control: Strict inspection and measurement of every product

Application: Widely used in aerospace, automotive, electronics, and other industries

Advantages: High precision, complex shapes achievable, efficient production, cost-effective

Special Requirements: Customized surface treatment, specific material selection, tight tolerances, etc.

| Product name | Aluminum 6061 6060 surface oxide Mechanical CNC Machining Parts,cnc turning machined anodized mechanical parts,auto spare parts |

| Certification | ISO9001, SGS, ROHS |

| Material | Aluminum |

| Surface | Black Anodized |

| Process | CNC Turning and milling |

| Tolerance | +/-0.01mm |

| Quality control | 100% inspected |

| Specification | OEM serice, strictly according drawing and samples |

| Sample delivery time | 5-7 days, per products |

| Application | OEM CNC Machining, Machinery Accessoried, Auto Parts, Industrial Parts, Automation equipment Parts, Testing Equipment Parts, Motor Parts, Spare parts , Auto spare parts Led Flashlight Parts, etc |

1 off cnc machining bearings FAQs Guide 1 off cnc machining offers a wide range of capabilities, including milling, turning, drilling, and grinding, to produce parts with tight tolerances, intricate designs, and smooth surface finishes. This process is used in a variety of industries, including automotive, aerospace, medical, and electronics, to create high-quality components for everything from engine parts to surgical instruments.

2.Are complex shapes and curves possible with 1 off cnc machining?

3.What is the role of programming software in 1 off cnc machining?

4.Is 1 off cnc machining environmentally friendly?

5.How does the cost of 1 off cnc machining compare to traditional machining methods?

6.How do I maintain a CNC machine?

7.What are the benefits of using 1 off cnc machining?

8.What is the role of computer-aided design in 1 off cnc machining?

9.Are there any limitations to the shapes that can be produced with 1 off cnc machining?

10.What is the role of coolant in 1 off cnc machining?

11.What industries commonly use 1 off cnc machining?

12.How precise is 1 off cnc machining?

13.What is the role of CAD/CAM software in 1 off cnc machining?

1.How does 1 off cnc machining help reduce material waste?

We have a professional team that is committed to the innovation and development of 1 off cnc machining.

CNC machining is a highly precise method of metalworking that uses computer-controlled machines to cut, shape, and finish metal parts. One of the biggest advantages of CNC machining is that it helps to reduce material waste by maximizing the use of raw materials. The use of pre-programmed computer software allows for precise and efficient cutting, minimizing the amount of material that is removed or wasted during the manufacturing process. This not only helps to save on material costs, but also helps to reduce the environmental impact of manufacturing by reducing the amount of scrap and excess material. Overall, CNC machining helps to optimize production processes and reduce material waste, making it a more cost-effective and sustainable method of manufacturing.

2.Are complex shapes and curves possible with 1 off cnc machining?

We pay attention to the introduction and training of talents, scientifically regulate the management system, and focus on cultural construction and team cohesion. Yes, complex shapes and curves are possible with CNC machining. CNC (Computer Numerical Control) machining is a versatile manufacturing process that uses computer-controlled machines to remove material from a workpiece to create a desired shape. This process allows for precise and intricate designs to be achieved, including complex shapes and curves. CNC machines can be programmed to follow specific tool paths and make precise cuts, allowing for the creation of intricate and complex shapes. Additionally, CNC machines can use different types of cutting tools, such as end mills and ball mills, to achieve different shapes and curves. With the right programming and tooling, CNC machining can produce highly detailed and complex parts with tight tolerances.

3.What is the role of programming software in 1 off cnc machining?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously.

Some of the key functions of programming software in CNC machining include:

1. Creating and editing toolpaths: Programming software allows users to create and edit toolpaths, which are the specific paths that the cutting tool will follow to create the desired shape or design.

2. Defining cutting parameters: The software also allows users to specify the cutting parameters such as speed, feed rate, and depth of cut, which are essential for achieving the desired results.

3. Simulating and optimizing programs: Before running the program on the actual machine, the software allows users to simulate and optimize the program to identify any potential issues or errors.

4. Generating G-code: G-code is the language that CNC machines understand, and programming software is responsible for generating this code based on the user's instructions.

5. Managing multiple axes: CNC machines can have multiple axes of movement, and programming software allows users to control and coordinate these axes to create complex shapes and designs.

6. Integrating with CAD/CAM software: Programming software can also integrate with CAD/CAM software, allowing users to directly import designs and models into the program for easier programming.

4.Is 1 off cnc machining environmentally friendly?

CNC machining can be environmentally friendly if sustainable materials are used and if the machining process is optimized to reduce waste. CNC machines also have the ability to recycle and reuse excess material, minimizing the overall environmental impact.

5.How does the cost of 1 off cnc machining compare to traditional machining methods?

As one of the 1 off cnc machining market leaders, we are known for innovation and reliability.

The cost of CNC machining can vary depending on factors such as the complexity of the part, the material being used, and the quantity being produced. However, in general, CNC machining tends to be more cost-effective than traditional machining methods.

One reason for this is that CNC machines can operate continuously without the need for breaks or rest, resulting in faster production times and lower labor costs. Additionally, CNC machines can produce highly precise and accurate parts, reducing the need for manual adjustments and minimizing material waste.

Traditional machining methods, on the other hand, often require more manual labor and can be slower and less precise, leading to higher labor costs and more material waste. They may also require multiple machines and processes to produce a single part, adding to the overall cost.

Overall, while the initial investment in CNC machines may be higher, the long-term cost savings and efficiency make it a more cost-effective option compared to traditional machining methods.

6.How do I maintain a CNC machine?

Regular maintenance is essential to ensure the optimal performance and longevity of a CNC machine. This includes cleaning, lubricating, and checking for wear and tear of the cutting tools and machine components.

7.What are the benefits of using 1 off cnc machining?

We should enjoy a good reputation in the industry, and we can increase the added value of the products of cooperative customers through technological innovation.

There are several benefits to using CNC machining, including increased precision, cost-effectiveness, efficiency, and versatility. With CNC machining, complex and intricate designs can be easily achieved, resulting in more precise and consistent parts. This leads to lower rejection rates and less material waste, making it a cost-effective option for production.

Additionally, CNC machines can operate 24/7, reducing production time and increasing efficiency. They can also be programmed to perform various types of cuts and operations, making them suitable for a wide range of applications. Furthermore, CNC machines offer a higher level of automation and require less human labor, minimizing the risk of errors and accidents. Overall, CNC machining offers numerous advantages over traditional manufacturing methods, making it a popular choice for many industries.

8.What is the role of computer-aided design in 1 off cnc machining?

Computer-aided design (CAD) plays a crucial role in CNC machining by providing precise and detailed digital designs that can be directly converted into machine-readable code. This streamlines the production process and eliminates the need for manual drawings, reducing the risk of errors. CAD also allows for virtual testing and prototyping, improving the accuracy and efficiency of CNC machines. Furthermore, with the advancements in CAD software, complex and intricate designs can be created, expanding the capabilities and possibilities of CNC machining. Overall, CAD significantly enhances the speed, accuracy, and flexibility of CNC machining, making it an essential tool for the modern manufacturing industry.

9.Are there any limitations to the shapes that can be produced with 1 off cnc machining?

CNC machining is a computer-controlled manufacturing process that uses precise cutting tools to create various shapes and designs from a wide range of materials. While this advanced technology offers numerous benefits, there are also some limitations to the shapes that can be produced. Factors such as the size and complexity of the design, the capabilities of the machine, and the properties of the material being used can all impact the shapes that can be achieved through CNC machining. Additionally, intricate and highly detailed designs may be more difficult, time-consuming, and costly to produce using this method. Despite these limitations, CNC machining remains a highly versatile and popular method for producing customized and precise parts and products.

10.What is the role of coolant in 1 off cnc machining?

Coolant, also known as cutting fluid, plays a crucial role in CNC machining. It is used to cool down the cutting tool and workpiece, lubricate the cutting edge, and remove chips and debris from the cutting area. This helps prevent overheating and tool wear, improves the surface finish of the final product, and prolongs the lifespan of the cutting tool. In addition, coolant also acts as a barrier between the cutting tool and workpiece, reducing friction and minimizing the risk of machined parts sticking together. Overall, the use of coolant in CNC machining helps enhance productivity, accuracy, and efficiency in the manufacturing process.

11.What industries commonly use 1 off cnc machining?

1. Automotive and Aerospace: These industries rely heavily on CNC machining for the production of precision parts, such as engine components, jet engine parts, and aircraft structural components.

2. Medical: CNC machining is used in the production of medical devices and implants, as well as for prototyping and creating custom tools and instruments.

3. Electronics: The electronics industry uses CNC machining for the production of complex and precise components, such as circuit boards and computer components.

4. Tool and die making: CNC machining is used in the manufacturing of molds, dies, and other tooling used in the production of various products.

5. Energy: CNC machining is used in the production of components for the energy industry, including parts for turbines, generators, and oil and gas equipment.

6. Defense and military: CNC machining is used in the production of various military equipment and weapons, such as firearms, aircraft parts, and vehicle components.

7. Consumer goods: CNC machining is used in the production of everyday consumer products, such as kitchen appliances, home goods, and furniture.

8. Prototyping and product development: Many industries use CNC machining in the prototyping and product development stage to create models and prototypes for testing and refinement.

9. Agriculture: CNC machining is used in the production of machinery and equipment used in agriculture, such as tractors, harvesters, and irrigation systems.

10. Jewelry: The jewelry industry uses CNC machining to create intricate and precise designs for pieces such as rings, pendants, and earrings.

12.How precise is 1 off cnc machining?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. CNC machining is known for its high precision and accuracy. The level of precision can vary depending on the specific machine, tooling, and materials used, but in general, CNC machining can achieve tolerances as tight as 0.001 inches (0.0254 mm). This level of precision is much higher than what can be achieved through manual machining methods. Additionally, CNC machines can consistently produce parts with the same level of precision, making them ideal for high-volume production.

13.What is the role of CAD/CAM software in 1 off cnc machining?

CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software plays a crucial role in CNC (Computer Numerical Control) machining. It is a software tool that allows designers and engineers to create detailed 3D models of parts and products, and then use those models to generate instructions for CNC machines to manufacture those parts.

The CAD component of the software is used to design and create the 3D models of the parts. This allows for precise and accurate design, as well as the ability to make changes and modifications easily. The CAM component of the software is used to generate the toolpaths and instructions that the CNC machine will use to manufacture the part. This includes specifying the cutting tools, speeds, feeds, and other parameters necessary for the CNC machine to produce the desired part.

CAD/CAM software also allows for simulation and testing of the machining process before it is actually carried out on the CNC machine. This helps to identify any potential issues or errors in the design or toolpaths, saving time and resources.

Our Headquarters

6/F,Tiankaisheng Business Building, Building 46th.,No. 25th Quater,Gongming Str., Guangming, Shenzhen,ChinaLearn More