1 day cnc machining

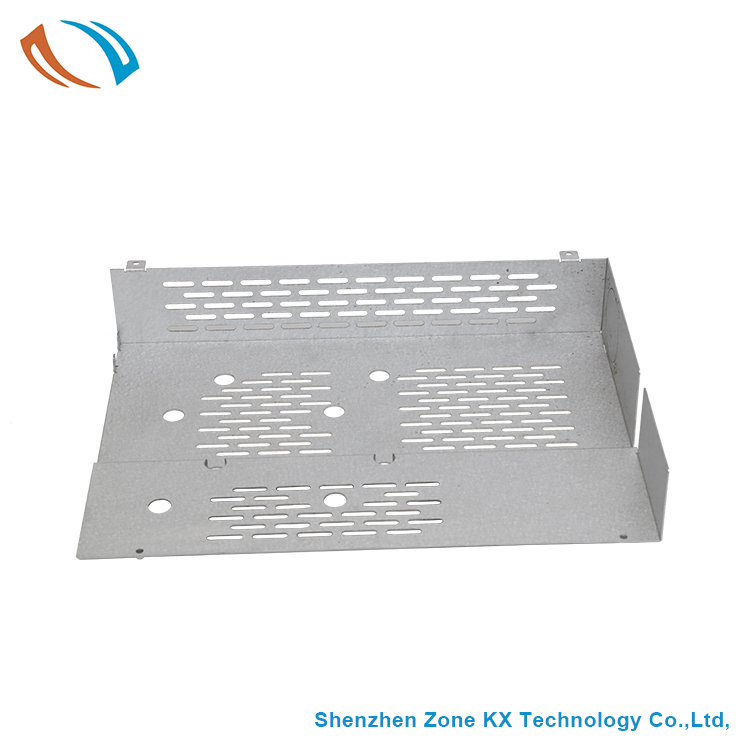

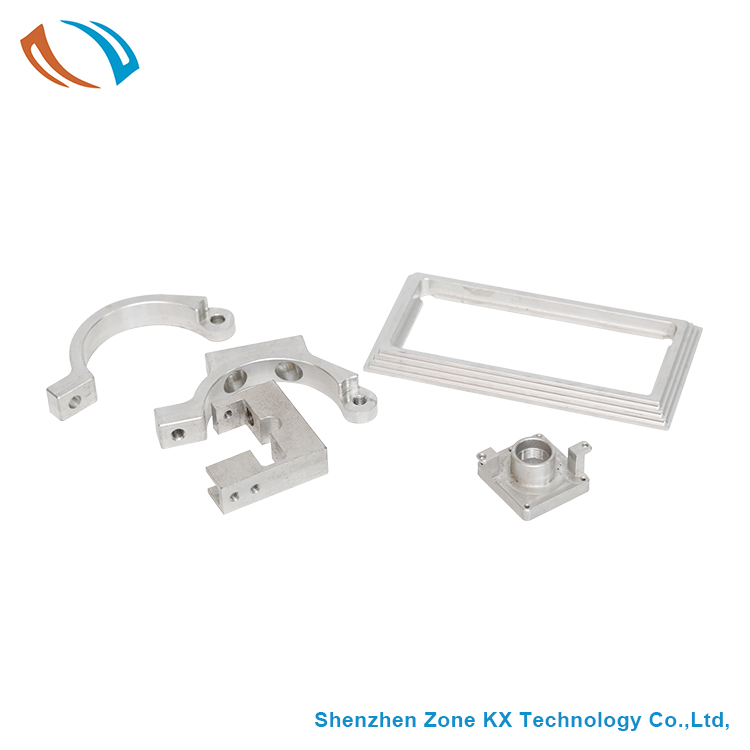

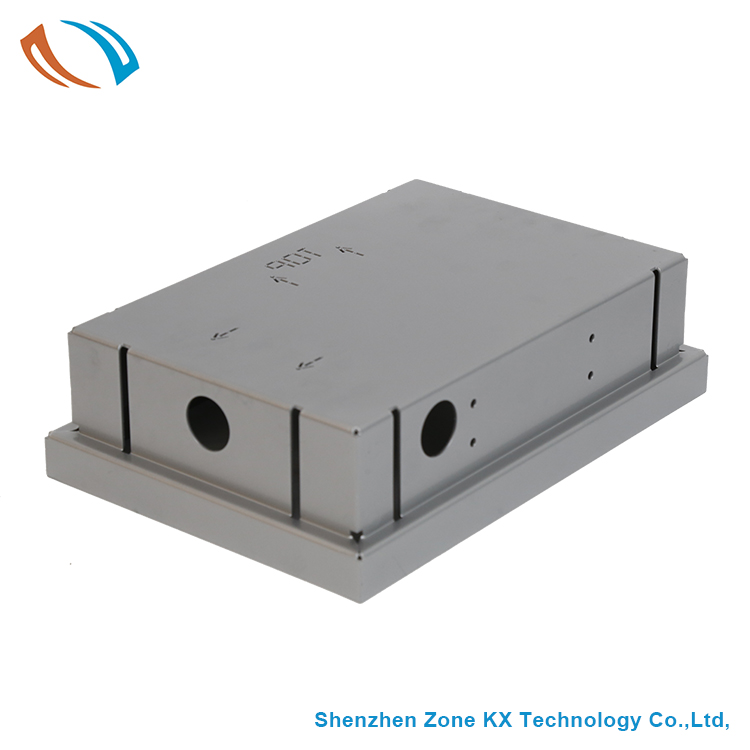

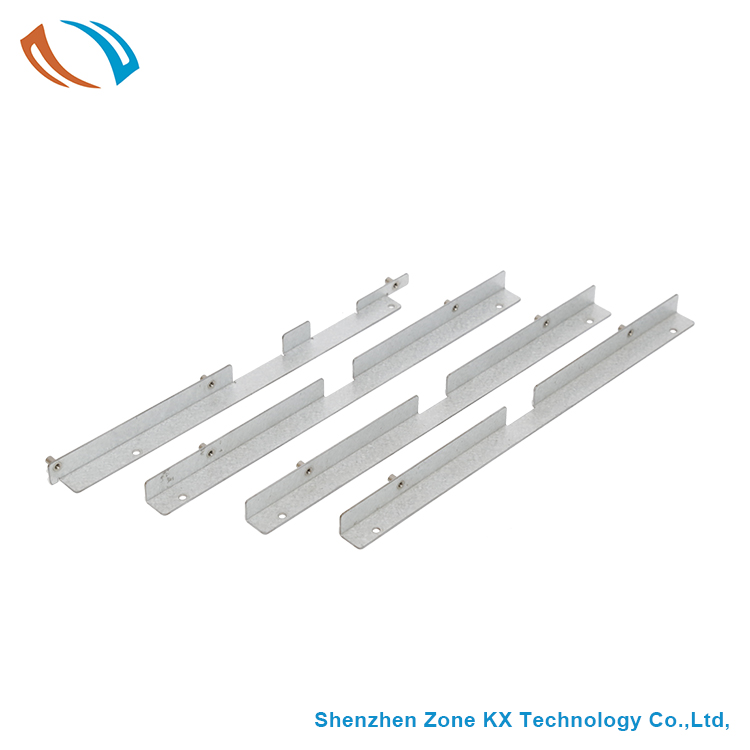

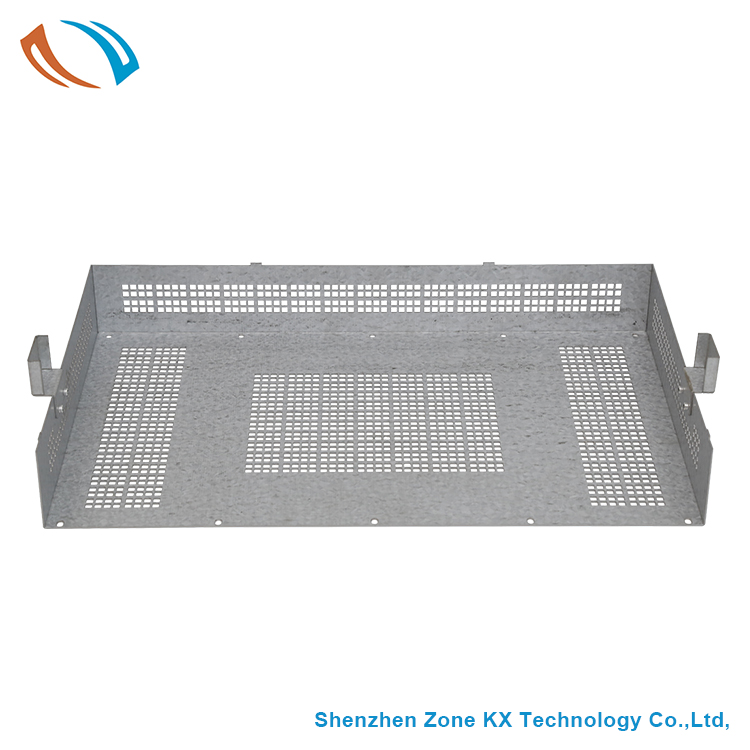

Product Name: CNC Machining ProductProduct Type: Mechanical Component

Production Materials: Various Metals (Aluminum, Steel, Titanium, etc.)

Production Process: CNC Machining

Dimension Tolerance: +/- 0.01mm

Surface Finish: Smooth (Ra < 0.8um)

Product Strength: High

Product Accuracy: Precise

Production Capacity: Customized according to customer requirements

Lead Time: Variable, depending on product complexity and quantity

Quality Control: Strict inspection and measurement of every product

Application: Widely used in aerospace, automotive, electronics, and other industries

Advantages: High precision, complex shapes achievable, efficient production, cost-effective

Special Requirements: Customized surface treatment, specific material selection, tight tolerances, etc.

The cornerstone of ZONE-KX Technology's success is customer service at every step of the pre-sales and after-sales process. We work closely with our customers first to identify their exact needs during the design process and commit to planning to prevent costly errors and delays during manufacturing and after delivery. Our skilled staff will strive to thoroughly understand your requirements. Our skills, knowledge, and rich experience are dedicated to meeting your needs, making our customers feel that Chuanghe is not only a supplier, but also a partner.

| Processing category | Custom CNC Machining Parts of Most Materials |

| Quotation | According to your drawing(size, material, thickness, processing content, and required technology, etc) |

| Tolerance丨Surface Roughness | +/-0.005 - 0.01mm 丨 Ra0.2 - Ra3.2(Custonize avaiable) |

| Materials Avaiable | Aluminum, Copper, Stainless steel, Iron, PE, PVC, ABS, etc. |

| Surface Treatment | Polishing, general/hard/color oxidation, surface chamfering, tempering, etc. |

| Processing | CNC Turning, Milling, drilling, auto lathe, tapping, bushing, surface treatment, etc. |

| Testing Equipment | CMM/Tool microscope/multi-joint arm/Automatic height gauge/Manual height gauge/Dial gauge/Roughness measurement |

| Drawing Formats | PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF |

| Our Advantages | 1. 24 hours online service & Quickly Quote/Delivery. 2. 100% QC quality inspection before delivery, and can provide quality inspection form. 3. 16+ years of experience in the CNC machining area and have a senior design team to offer perfect modification suggestions. |

1 day cnc machining bearings FAQs Guide 1 day cnc machining offers a wide range of capabilities, including milling, turning, drilling, and grinding, to produce parts with tight tolerances, intricate designs, and smooth surface finishes. This process is used in a variety of industries, including automotive, aerospace, medical, and electronics, to create high-quality components for everything from engine parts to surgical instruments.

2.Is 1 day cnc machining suitable for mass production?

3.What is the difference between CNC milling and CNC turning?

4.What are the limitations of 1 day cnc machining?

5.What industries commonly use 1 day cnc machining?

6.How does 1 day cnc machining compare to manual polishing and finishing processes?

7.How does 1 day cnc machining work?

8.How long does it take to set up a CNC machine?

9.What is the role of computer-aided design in 1 day cnc machining?

10.How does 1 day cnc machining affect the overall cost of production?

11.How does 1 day cnc machining compare to laser cutting?

12.What role do sensors play in 1 day cnc machining?

13.Are complex shapes and curves possible with 1 day cnc machining?

14.Are there any environmental benefits of using 1 day cnc machining?

15.Can CNC machines create threads and screw holes?

1.Are there any recycling options for materials used in 1 day cnc machining?

Yes, there are several recycling options for materials used in CNC machining, such as aluminum, steel, and plastic. These materials can be melted down and reused for new products or repurposed for other industrial applications. Some CNC machine shops also have their own recycling programs in place to properly dispose of and recycle scrap materials generated during the machining process. Additionally, there are recycling facilities that specialize in handling industrial waste and scrap metals from CNC machining, ensuring that these materials are responsibly processed and reused.

2.Is 1 day cnc machining suitable for mass production?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, CNC machining is suitable for mass production. CNC machines are highly efficient and can produce large quantities of parts with consistent quality and accuracy. They also have the ability to run continuously, reducing production time and increasing output. Additionally, CNC machines can be programmed to produce multiple parts simultaneously, further increasing production efficiency. With proper planning and optimization, CNC machining can be a cost-effective solution for mass production.

3.What is the difference between CNC milling and CNC turning?

CNC milling uses rotating cutting tools to remove material from a stationary workpiece, while CNC turning rotates the workpiece against a stationary cutting tool to create rotational parts such as cylinders and cones.

4.What are the limitations of 1 day cnc machining?

CNC machining may have higher initial costs compared to other manufacturing methods and may not be suitable for very small or intricate parts. It also requires programming and setup time for each new design, making it more suitable for larger production runs.

5.What industries commonly use 1 day cnc machining?

1. Automotive and Aerospace: These industries rely heavily on CNC machining for the production of precision parts, such as engine components, jet engine parts, and aircraft structural components.

2. Medical: CNC machining is used in the production of medical devices and implants, as well as for prototyping and creating custom tools and instruments.

3. Electronics: The electronics industry uses CNC machining for the production of complex and precise components, such as circuit boards and computer components.

4. Tool and die making: CNC machining is used in the manufacturing of molds, dies, and other tooling used in the production of various products.

5. Energy: CNC machining is used in the production of components for the energy industry, including parts for turbines, generators, and oil and gas equipment.

6. Defense and military: CNC machining is used in the production of various military equipment and weapons, such as firearms, aircraft parts, and vehicle components.

7. Consumer goods: CNC machining is used in the production of everyday consumer products, such as kitchen appliances, home goods, and furniture.

8. Prototyping and product development: Many industries use CNC machining in the prototyping and product development stage to create models and prototypes for testing and refinement.

9. Agriculture: CNC machining is used in the production of machinery and equipment used in agriculture, such as tractors, harvesters, and irrigation systems.

10. Jewelry: The jewelry industry uses CNC machining to create intricate and precise designs for pieces such as rings, pendants, and earrings.

6.How does 1 day cnc machining compare to manual polishing and finishing processes?

CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls to operate precision machine tools. In contrast, manual polishing and finishing processes involve the use of hand tools and techniques to create a desired surface finish on a workpiece. While both methods can achieve high-quality results, there are some key differences between CNC machining and manual polishing and finishing processes. CNC machining offers greater precision and consistency due to the use of computer programs to control the movement of the machine, while manual processes are more reliant on the skill and technique of the operator.

Additionally, CNC machining is faster and more efficient, as it can produce multiple identical parts in a shorter amount of time compared to manual methods. However, manual polishing and finishing processes may be more cost-effective for smaller production runs or for parts with complex shapes that are difficult to machine. Overall, the choice between CNC machining and manual polishing and finishing processes depends on the specific requirements of the project and the desired end result.

7.How does 1 day cnc machining work?

We pay attention to user experience and product quality, and provide the best product quality and lowest production cost for cooperative customers.

CNC (Computer Numerical Control) machining is a process that uses computerized controls to operate and manipulate machines and tools for manufacturing and production purposes. It involves creating a digital design or model of the desired product which is then translated into a series of computer numerical codes, also known as G-codes. These codes are used to direct and control the movements of the machine's axes, such as the speed, direction, and positioning of the cutting tools. This precision-guided automation allows for efficient and accurate production of complex parts and components with minimal human involvement. The CNC machining process has revolutionized the manufacturing industry, allowing for greater productivity, consistency, and cost-effectiveness in the production of various products.

8.How long does it take to set up a CNC machine?

The setup time for a CNC machine depends on the complexity of the design and the experience of the operator, but it can typically take a few minutes to a few hours.

9.What is the role of computer-aided design in 1 day cnc machining?

Computer-aided design (CAD) plays a crucial role in CNC machining by providing precise and detailed digital designs that can be directly converted into machine-readable code. This streamlines the production process and eliminates the need for manual drawings, reducing the risk of errors. CAD also allows for virtual testing and prototyping, improving the accuracy and efficiency of CNC machines. Furthermore, with the advancements in CAD software, complex and intricate designs can be created, expanding the capabilities and possibilities of CNC machining. Overall, CAD significantly enhances the speed, accuracy, and flexibility of CNC machining, making it an essential tool for the modern manufacturing industry.

10.How does 1 day cnc machining affect the overall cost of production?

CNC machining can affect the overall cost of production in several ways:

1. Labor costs: CNC machining reduces the need for manual labor, as the machines are automated and require minimal human intervention. This can result in lower labor costs, as fewer workers are needed to operate the machines.

2. Material costs: CNC machines are highly precise and efficient, which means they can produce parts with minimal waste. This can result in lower material costs, as less material is needed to produce the same number of parts.

3. Setup costs: CNC machines can be programmed to produce a wide range of parts, which reduces the need for frequent setup changes. This can result in lower setup costs, as less time and effort is required to switch between different parts.

4. Production speed: CNC machines can produce parts at a much faster rate than manual machining, which can result in higher production volumes in a shorter amount of time. This can lead to lower overall production costs, as more parts can be produced in a given time period.

5. Quality control: CNC machines are highly accurate and produce consistent results, which reduces the need for quality control checks and rework. This can result in lower costs associated with quality control and rework.

11.How does 1 day cnc machining compare to laser cutting?

CNC machining and laser cutting are both popular manufacturing methods used in various industries. CNC machining, or computer numerical control machining, involves the use of computer-controlled machines to create complex parts and products from various materials. On the other hand, laser cutting uses a high-powered laser beam to cut and shape materials into precise shapes and sizes.

While both methods have their own advantages and limitations, CNC machining is generally preferred for its ability to handle a wider range of materials and create more intricate and precise designs. It also allows for more flexibility in terms of customization and can be used for both prototype and production runs. Laser cutting, on the other hand, excels in cutting thin materials quickly and with high levels of precision. It is also ideal for creating intricate designs with smooth edges.

12.What role do sensors play in 1 day cnc machining?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market.

Some common types of sensors used in CNC machining include:

1. Position sensors: These sensors are used to measure the position of the tool, workpiece, or other machine components. They provide feedback to the control system, which helps in precise positioning and movement of the machine.

2. Speed sensors: These sensors are used to measure the rotational speed of the spindle or the linear speed of the tool. They help in maintaining the desired cutting speed and detecting any abnormalities in the machine's speed.

3. Temperature sensors: These sensors are used to monitor the temperature of the machine components, such as the spindle, motor, and cutting tool. They help in preventing overheating and ensuring the machine operates within safe temperature limits.

4. Pressure sensors: These sensors are used to measure the pressure exerted by the cutting tool on the workpiece. They help in detecting any changes in cutting forces, which can indicate tool wear or material inconsistencies.

13.Are complex shapes and curves possible with 1 day cnc machining?

We pay attention to the introduction and training of talents, scientifically regulate the management system, and focus on cultural construction and team cohesion. Yes, complex shapes and curves are possible with CNC machining. CNC (Computer Numerical Control) machining is a versatile manufacturing process that uses computer-controlled machines to remove material from a workpiece to create a desired shape. This process allows for precise and intricate designs to be achieved, including complex shapes and curves. CNC machines can be programmed to follow specific tool paths and make precise cuts, allowing for the creation of intricate and complex shapes. Additionally, CNC machines can use different types of cutting tools, such as end mills and ball mills, to achieve different shapes and curves. With the right programming and tooling, CNC machining can produce highly detailed and complex parts with tight tolerances.

14.Are there any environmental benefits of using 1 day cnc machining?

Our 1 day cnc machining products have competitive and differentiated advantages, and actively promote digital transformation and innovation.

Yes, there are several environmental benefits of using CNC (Computer Numerical Control) machining.

Firstly, CNC machining is highly efficient and precise, which means it can produce parts with minimal waste and reduced scrap material. This not only saves resources and reduces the amount of material sent to landfills, but it also lowers the environmental impact associated with traditional machining processes that generate more waste.

Secondly, CNC machining often uses advanced cutting tools and techniques, resulting in a more energy-efficient process. This means less energy consumption and a reduction in carbon emissions.

Additionally, since CNC machining is a computer-controlled process, it significantly reduces the potential for human error. This results in minimized rework and scrap parts, which ultimately reduces the amount of energy, resources, and waste used in the manufacturing process.

15.Can CNC machines create threads and screw holes?

Yes, CNC (Computer Numerical Control) machines can be programmed to create threads and screw holes in various materials such as metal, plastic, and wood. This process is typically achieved by using a tap or a thread mill to cut the desired thread pattern into the material. CNC machines have the ability to precisely control cutting tools, allowing for accurate thread creation and consistency. They can also be programmed to create different types of threads, such as metric or imperial, depending on the project requirements.

Our Headquarters

6/F,Tiankaisheng Business Building, Building 46th.,No. 25th Quater,Gongming Str., Guangming, Shenzhen,ChinaLearn More