2 axis cnc milling

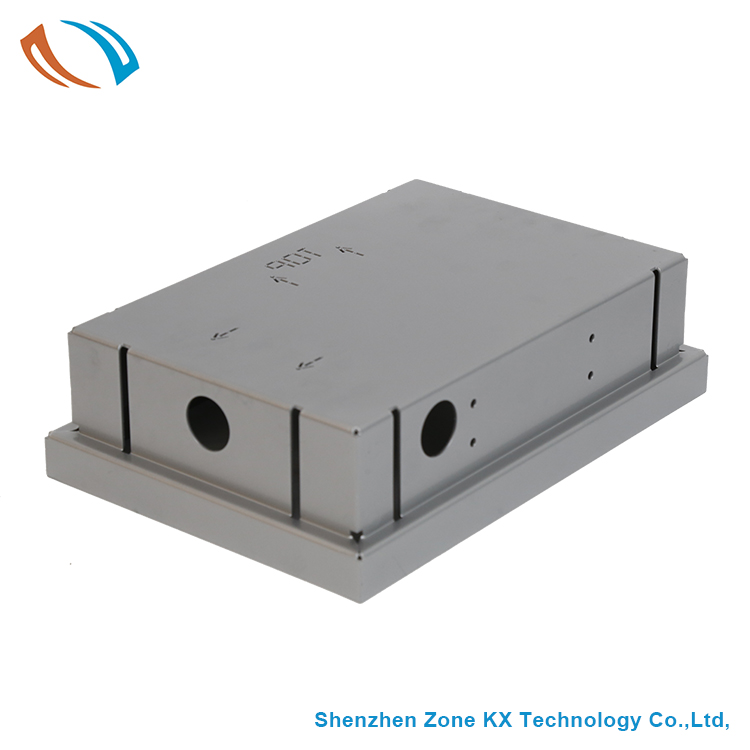

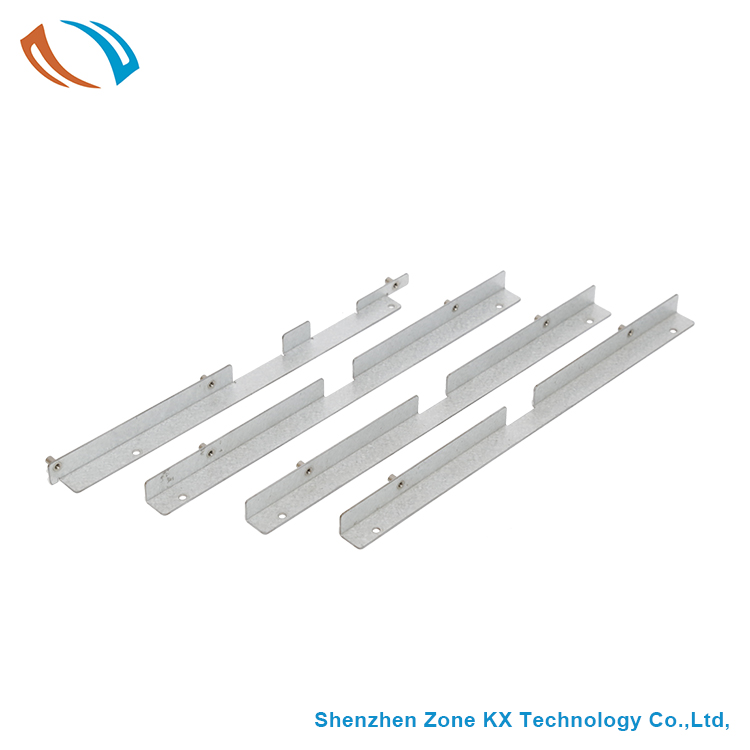

Product Name: CNC Machining ProductProduct Type: Mechanical Component

Production Materials: Various Metals (Aluminum, Steel, Titanium, etc.)

Production Process: CNC Machining

Dimension Tolerance: +/- 0.01mm

Surface Finish: Smooth (Ra < 0.8um)

Product Strength: High

Product Accuracy: Precise

Production Capacity: Customized according to customer requirements

Lead Time: Variable, depending on product complexity and quantity

Quality Control: Strict inspection and measurement of every product

Application: Widely used in aerospace, automotive, electronics, and other industries

Advantages: High precision, complex shapes achievable, efficient production, cost-effective

Special Requirements: Customized surface treatment, specific material selection, tight tolerances, etc.

The cornerstone of ZONE-KX Technology's success is customer service at every step of the pre-sales and after-sales process. We work closely with our customers first to identify their exact needs during the design process and commit to planning to prevent costly errors and delays during manufacturing and after delivery. Our skilled staff will strive to thoroughly understand your requirements. Our skills, knowledge, and rich experience are dedicated to meeting your needs, making our customers feel that Chuanghe is not only a supplier, but also a partner.

| Product name | Aluminum 6061 6060 surface oxide Mechanical CNC Machining Parts,cnc turning machined anodized mechanical parts,auto spare parts |

| Certification | ISO9001, SGS, ROHS |

| Material | Aluminum |

| Surface | Black Anodized |

| Process | CNC Turning and milling |

| Tolerance | +/-0.01mm |

| Quality control | 100% inspected |

| Specification | OEM serice, strictly according drawing and samples |

| Sample delivery time | 5-7 days, per products |

| Application | OEM CNC Machining, Machinery Accessoried, Auto Parts, Industrial Parts, Automation equipment Parts, Testing Equipment Parts, Motor Parts, Spare parts , Auto spare parts Led Flashlight Parts, etc |

2 axis cnc milling bearings FAQs Guide 2 axis cnc milling offers a wide range of capabilities, including milling, turning, drilling, and grinding, to produce parts with tight tolerances, intricate designs, and smooth surface finishes. This process is used in a variety of industries, including automotive, aerospace, medical, and electronics, to create high-quality components for everything from engine parts to surgical instruments.

2.What is the difference between a CNC machine and a 3D printer?

3.How does 2 axis cnc milling ensure the safety of the operator?

4.How accurate is 2 axis cnc milling?

5.What file formats are compatible with 2 axis cnc milling?

6.Can 2 axis cnc milling be done on curved or irregularly shaped surfaces?

7.What is the role of programming software in 2 axis cnc milling?

8.How does 2 axis cnc milling work?

9.What role do sensors play in 2 axis cnc milling?

10.Can CNC machines create threads and screw holes?

11.What are the benefits of using 2 axis cnc milling?

12.What types of tools are used in 2 axis cnc milling?

13.What is the cost of 2 axis cnc milling compared to other manufacturing methods?

14.Can CNC machines work with multiple axes?

15.Can 2 axis cnc milling be used for mass production?

16.How does 2 axis cnc milling handle tight tolerances?

1.What types of CNC machines are there?

There are several types of CNC machines, including mills, lathes, routers, grinders, and lasers. Each type is designed for specific applications and materials.

2.What is the difference between a CNC machine and a 3D printer?

While both CNC machines and 3D printers use computer-controlled technology to create precise parts, CNC machines use subtractive manufacturing techniques by cutting away material, while 3D printers use additive manufacturing by adding layers of material to create a part.

3.How does 2 axis cnc milling ensure the safety of the operator?

CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-controlled machines to produce high-precision parts and components. This technology has revolutionized the manufacturing industry by increasing productivity and efficiency. Apart from its benefits in terms of production, CNC machining also prioritizes the safety of the operator.

One way CNC machining ensures the safety of the operator is by eliminating the need for direct contact with cutting tools. The entire process is automated, and the operator only needs to input the design and specifications into the computer. This removes the risk of accidents and injuries that may occur when handling sharp tools and heavy machinery.

Moreover, CNC machines are equipped with safety features such as sensors and emergency stops to prevent any potential hazards. These sensors can detect any malfunctions or errors in the system, which would then trigger the emergency stop, shutting down the machine and preventing any injuries.

4.How accurate is 2 axis cnc milling?

CNC machining is highly accurate, with tolerances as small as 0.001 inches depending on the material and design specifications.

5.What file formats are compatible with 2 axis cnc milling?

Common file formats used in CNC machining include STEP, IGES, and STL for 3D designs, and DWG, DXF, and PDF for 2D drawings.

6.Can 2 axis cnc milling be done on curved or irregularly shaped surfaces?

Yes, CNC machining can be done on curved or irregularly shaped surfaces. CNC machines use computer programming and advanced tooling to precisely cut and shape materials. The machine is able to follow complex and irregular curves by using specialized software to convert the design into a series of movement instructions for the machine's cutting tools. This allows for intricate and accurate machining on curved or irregularly shaped surfaces.

7.What is the role of programming software in 2 axis cnc milling?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously.

Some of the key functions of programming software in CNC machining include:

1. Creating and editing toolpaths: Programming software allows users to create and edit toolpaths, which are the specific paths that the cutting tool will follow to create the desired shape or design.

2. Defining cutting parameters: The software also allows users to specify the cutting parameters such as speed, feed rate, and depth of cut, which are essential for achieving the desired results.

3. Simulating and optimizing programs: Before running the program on the actual machine, the software allows users to simulate and optimize the program to identify any potential issues or errors.

4. Generating G-code: G-code is the language that CNC machines understand, and programming software is responsible for generating this code based on the user's instructions.

5. Managing multiple axes: CNC machines can have multiple axes of movement, and programming software allows users to control and coordinate these axes to create complex shapes and designs.

6. Integrating with CAD/CAM software: Programming software can also integrate with CAD/CAM software, allowing users to directly import designs and models into the program for easier programming.

8.How does 2 axis cnc milling work?

CNC machines use computer-aided design (CAD) and computer-aided manufacturing (CAM) software to guide the cutting tools and move the workpiece, which is held in place by a vice or clamp, in a precise and programmed manner.

9.What role do sensors play in 2 axis cnc milling?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market.

Some common types of sensors used in CNC machining include:

1. Position sensors: These sensors are used to measure the position of the tool, workpiece, or other machine components. They provide feedback to the control system, which helps in precise positioning and movement of the machine.

2. Speed sensors: These sensors are used to measure the rotational speed of the spindle or the linear speed of the tool. They help in maintaining the desired cutting speed and detecting any abnormalities in the machine's speed.

3. Temperature sensors: These sensors are used to monitor the temperature of the machine components, such as the spindle, motor, and cutting tool. They help in preventing overheating and ensuring the machine operates within safe temperature limits.

4. Pressure sensors: These sensors are used to measure the pressure exerted by the cutting tool on the workpiece. They help in detecting any changes in cutting forces, which can indicate tool wear or material inconsistencies.

10.Can CNC machines create threads and screw holes?

Yes, CNC (Computer Numerical Control) machines can be programmed to create threads and screw holes in various materials such as metal, plastic, and wood. This process is typically achieved by using a tap or a thread mill to cut the desired thread pattern into the material. CNC machines have the ability to precisely control cutting tools, allowing for accurate thread creation and consistency. They can also be programmed to create different types of threads, such as metric or imperial, depending on the project requirements.

11.What are the benefits of using 2 axis cnc milling?

We should enjoy a good reputation in the industry, and we can increase the added value of the products of cooperative customers through technological innovation.

There are several benefits to using CNC machining, including increased precision, cost-effectiveness, efficiency, and versatility. With CNC machining, complex and intricate designs can be easily achieved, resulting in more precise and consistent parts. This leads to lower rejection rates and less material waste, making it a cost-effective option for production.

Additionally, CNC machines can operate 24/7, reducing production time and increasing efficiency. They can also be programmed to perform various types of cuts and operations, making them suitable for a wide range of applications. Furthermore, CNC machines offer a higher level of automation and require less human labor, minimizing the risk of errors and accidents. Overall, CNC machining offers numerous advantages over traditional manufacturing methods, making it a popular choice for many industries.

12.What types of tools are used in 2 axis cnc milling?

We operate our 2 axis cnc milling business with integrity and honesty.

1. CNC Machines: These are the main tools used in CNC machining. They are computer-controlled machines that can perform a variety of operations such as cutting, drilling, milling, and turning.

2. Cutting Tools: These include drills, end mills, reamers, and other tools used to remove material from the workpiece.

3. Lathe Tools: These are used in lathe machines to shape and cut the workpiece.

4. Milling Tools: These include milling cutters, face mills, and other tools used to remove material from the workpiece in a milling machine.

5. Drilling Tools: These include drill bits, countersinks, and other tools used to create holes in the workpiece.

6. Grinding Tools: These include grinding wheels, abrasive belts, and other tools used to smooth and finish the surface of the workpiece.

7. Boring Tools: These are used to enlarge or shape existing holes in the workpiece.

8. EDM Tools: These include electrodes, wire, and other tools used in electrical discharge machining to cut and shape the workpiece.

9. Inspection Tools: These include calipers, micrometers, and other measuring tools used to ensure accuracy and precision in the machining process.

10. Software: CNC machining also requires specialized software to program and control the machines, such as CAD/CAM software.

13.What is the cost of 2 axis cnc milling compared to other manufacturing methods?

The cost of CNC machining can vary depending on the complexity of the design, material, and production quantity. In general, CNC machining may have a higher initial cost compared to traditional manufacturing methods, but can be more cost-effective in the long run for larger production runs.

14.Can CNC machines work with multiple axes?

Yes, CNC machines can work with multiple axes, including X, Y, and Z for 3D design, as well as rotary axes for more complex and intricate designs.

15.Can 2 axis cnc milling be used for mass production?

Yes, CNC machining is commonly used for mass production as it can produce consistent and high-quality parts at a faster rate compared to traditional manufacturing methods.

16.How does 2 axis cnc milling handle tight tolerances?

We have the leading technology and innovation capabilities, and attach importance to employee training and development, and provide promotion opportunities.

Here are the ways in which CNC machining can handle tight tolerances:

1. Accurate Programming: CNC machines are programmed using computer-aided design (CAD) software, which allows for precise and accurate design specifications. This ensures that the machine cuts the material to the exact dimensions specified in the design.

2. High Precision Tools: CNC machines use high precision cutting tools, such as drills, mills, and lathes, which are capable of cutting materials with high accuracy. These tools are also regularly calibrated to maintain their accuracy.

3. Automated Processes: CNC machines are fully automated, which eliminates the potential for human error. This ensures that the machining process is consistent and precise, resulting in tight tolerances.

4. Advanced Control Systems: CNC machines are equipped with advanced control systems that monitor and adjust the cutting process in real-time. This allows for adjustments to be made to the cutting speed, feed rate, and tool path to ensure tight tolerances are maintained.

5. Quality Control Measures: CNC machining also involves quality control measures, such as using precision measuring tools and performing inspections throughout the manufacturing process. This ensures that the final product meets the specified tolerances.

Our Headquarters

6/F,Tiankaisheng Business Building, Building 46th.,No. 25th Quater,Gongming Str., Guangming, Shenzhen,ChinaLearn More