wolfram steel cnc milling cutter

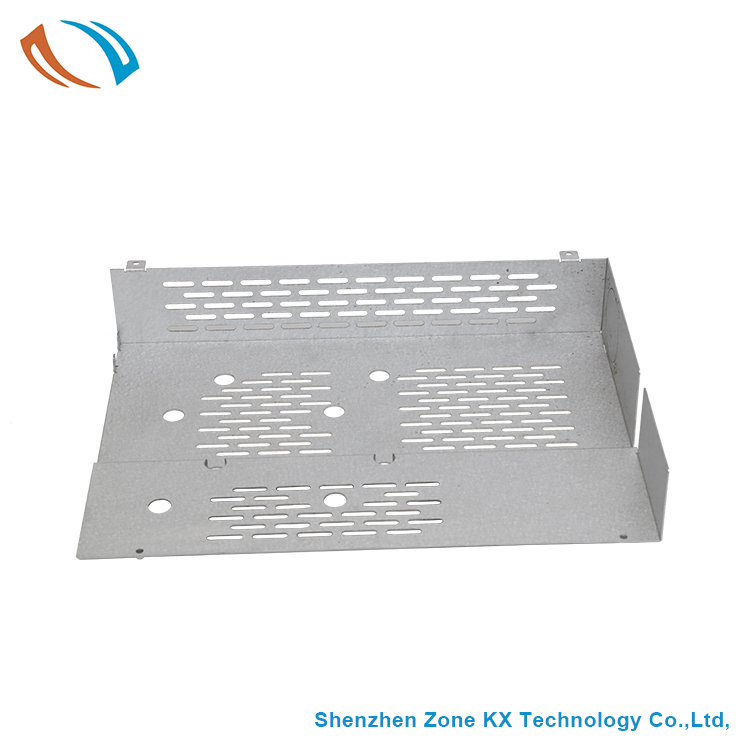

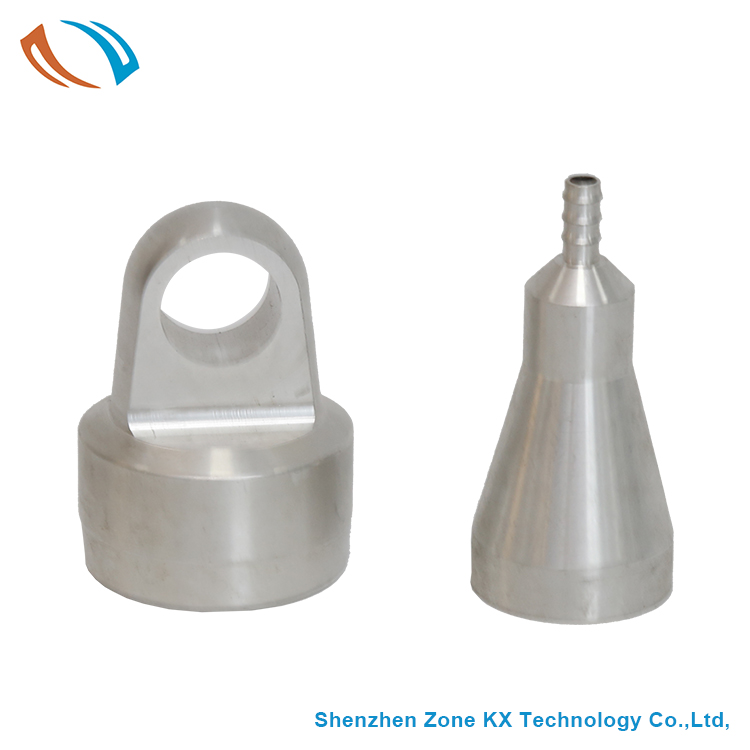

Product Name: CNC Machining ProductProduct Type: Mechanical Component

Production Materials: Various Metals (Aluminum, Steel, Titanium, etc.)

Production Process: CNC Machining

Dimension Tolerance: +/- 0.01mm

Surface Finish: Smooth (Ra < 0.8um)

Product Strength: High

Product Accuracy: Precise

Production Capacity: Customized according to customer requirements

Lead Time: Variable, depending on product complexity and quantity

Quality Control: Strict inspection and measurement of every product

Application: Widely used in aerospace, automotive, electronics, and other industries

Advantages: High precision, complex shapes achievable, efficient production, cost-effective

Special Requirements: Customized surface treatment, specific material selection, tight tolerances, etc.

We specialize in manufacturing custom/OEM/ODM machined parts. We strictly adhere to the GB/T19001-2016/ISO9001:2015 management system and continuously improve production and management. Ensure to provide customers with high quality products and services. Over the years, our products have entered various fields such as the electronics industry, new energy industry, military industry, clothing industry, furniture industry, lighting, automobile industry, machinery industry, etc. We have customers all over the world, including Costa Rica,Singapore,Dominican Republic,Mali,Cayman Islands and many other countries.

| Product name | Aluminum 6061 6060 surface oxide Mechanical CNC Machining Parts,cnc turning machined anodized mechanical parts,auto spare parts |

| Certification | ISO9001, SGS, ROHS |

| Material | Aluminum |

| Surface | Black Anodized |

| Process | CNC Turning and milling |

| Tolerance | +/-0.01mm |

| Quality control | 100% inspected |

| Specification | OEM serice, strictly according drawing and samples |

| Sample delivery time | 5-7 days, per products |

| Application | OEM CNC Machining, Machinery Accessoried, Auto Parts, Industrial Parts, Automation equipment Parts, Testing Equipment Parts, Motor Parts, Spare parts , Auto spare parts Led Flashlight Parts, etc |

wolfram steel cnc milling cutter bearings FAQs Guide wolfram steel cnc milling cutter offers a wide range of capabilities, including milling, turning, drilling, and grinding, to produce parts with tight tolerances, intricate designs, and smooth surface finishes. This process is used in a variety of industries, including automotive, aerospace, medical, and electronics, to create high-quality components for everything from engine parts to surgical instruments.

2.Does wolfram steel cnc milling cutter require specialized tools?

3.Are there any limitations to the size of parts that can be produced with wolfram steel cnc milling cutter?

4.What is the role of programming software in wolfram steel cnc milling cutter?

5.Is wolfram steel cnc milling cutter environmentally friendly?

6.How can I ensure the quality of CNC machined parts?

7.How does the cost of wolfram steel cnc milling cutter compare to traditional machining methods?

8.How does wolfram steel cnc milling cutter ensure the safety of the operator?

9.Can wolfram steel cnc milling cutter be used for mass production?

10.How precise is wolfram steel cnc milling cutter?

11.How is the cutting speed controlled in wolfram steel cnc milling cutter?

12.How does wolfram steel cnc milling cutter handle tight tolerances?

13.How does wolfram steel cnc milling cutter improve production efficiency?

14.What type of finishes can be created with wolfram steel cnc milling cutter?

15.What file formats are compatible with wolfram steel cnc milling cutter?

1.How do I maintain a CNC machine?

Regular maintenance is essential to ensure the optimal performance and longevity of a CNC machine. This includes cleaning, lubricating, and checking for wear and tear of the cutting tools and machine components.

2.Does wolfram steel cnc milling cutter require specialized tools?

Yes, CNC machining requires specialized tools such as CNC machines, cutting tools, measuring instruments, and computer software. These tools are specifically designed and calibrated for precision and accuracy in the CNC machining process.

3.Are there any limitations to the size of parts that can be produced with wolfram steel cnc milling cutter?

We are centered on customers and always pay attention to customers' needs for wolfram steel cnc milling cutter products.

Yes, there are limitations to the size of parts that can be produced with CNC machining. The size limitations depend on the specific machine and its capabilities, but generally, CNC machines have a maximum work envelope or working area that determines the largest size of parts that can be produced. Additionally, the size of the raw material used for the part may also limit the size of the final product. Other factors such as the complexity of the part and the machine's accuracy and precision may also affect the size of parts that can be produced.

4.What is the role of programming software in wolfram steel cnc milling cutter?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously.

Some of the key functions of programming software in CNC machining include:

1. Creating and editing toolpaths: Programming software allows users to create and edit toolpaths, which are the specific paths that the cutting tool will follow to create the desired shape or design.

2. Defining cutting parameters: The software also allows users to specify the cutting parameters such as speed, feed rate, and depth of cut, which are essential for achieving the desired results.

3. Simulating and optimizing programs: Before running the program on the actual machine, the software allows users to simulate and optimize the program to identify any potential issues or errors.

4. Generating G-code: G-code is the language that CNC machines understand, and programming software is responsible for generating this code based on the user's instructions.

5. Managing multiple axes: CNC machines can have multiple axes of movement, and programming software allows users to control and coordinate these axes to create complex shapes and designs.

6. Integrating with CAD/CAM software: Programming software can also integrate with CAD/CAM software, allowing users to directly import designs and models into the program for easier programming.

5.Is wolfram steel cnc milling cutter environmentally friendly?

CNC machining can be environmentally friendly if sustainable materials are used and if the machining process is optimized to reduce waste. CNC machines also have the ability to recycle and reuse excess material, minimizing the overall environmental impact.

6.How can I ensure the quality of CNC machined parts?

1. Use high-quality materials: The first step towards ensuring the quality of CNC machined parts is to use high-quality materials. Make sure to source materials from reputable suppliers who provide materials with consistent quality.

2. Conduct frequent checks during production: It is crucial to conduct regular checks during the production process to catch any defects or errors early on. This includes checking for accuracy, surface finish, and dimensions.

3. Maintain a clean and organized workshop: A clean and organized workshop is essential for producing high-quality parts. A cluttered and dirty environment can lead to errors, contamination, and poor quality parts.

4. Utilize precision measuring equipment: Precision measuring equipment such as calipers, micrometers, and laser scanners can be used to ensure the accuracy and tolerances of the parts being produced.

5. Adhere to design specifications: Make sure to closely follow the design specifications provided by the client. This includes dimensions, material requirements, and surface finish.

6. Implement quality control processes: Implementing quality control processes such as visual inspections, in-process checks, and final inspections can help catch any defects or errors before the parts are delivered.

7. Train and educate employees: Proper training and education of employees on CNC machining techniques, quality control processes, and equipment usage can help ensure consistent and high-quality production.

8. Use advanced CNC machinery: Investing in advanced CNC machinery with modern features such as automatic tool changers, high spindle speeds, and multi-axis capabilities can result in increased precision and improved quality of parts.

9. Collaborate with the client: Maintain open communication and collaborate with the client throughout the production process. This can help identify any issues or concerns early on and ensure that the final product meets their specifications and expectations.

10. Regular maintenance of equipment: Regular maintenance and calibration of CNC machines and equipment can help prevent errors and ensure that they are functioning at their best, resulting in high-quality parts.

7.How does the cost of wolfram steel cnc milling cutter compare to traditional machining methods?

As one of the wolfram steel cnc milling cutter market leaders, we are known for innovation and reliability.

The cost of CNC machining can vary depending on factors such as the complexity of the part, the material being used, and the quantity being produced. However, in general, CNC machining tends to be more cost-effective than traditional machining methods.

One reason for this is that CNC machines can operate continuously without the need for breaks or rest, resulting in faster production times and lower labor costs. Additionally, CNC machines can produce highly precise and accurate parts, reducing the need for manual adjustments and minimizing material waste.

Traditional machining methods, on the other hand, often require more manual labor and can be slower and less precise, leading to higher labor costs and more material waste. They may also require multiple machines and processes to produce a single part, adding to the overall cost.

Overall, while the initial investment in CNC machines may be higher, the long-term cost savings and efficiency make it a more cost-effective option compared to traditional machining methods.

8.How does wolfram steel cnc milling cutter ensure the safety of the operator?

CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-controlled machines to produce high-precision parts and components. This technology has revolutionized the manufacturing industry by increasing productivity and efficiency. Apart from its benefits in terms of production, CNC machining also prioritizes the safety of the operator.

One way CNC machining ensures the safety of the operator is by eliminating the need for direct contact with cutting tools. The entire process is automated, and the operator only needs to input the design and specifications into the computer. This removes the risk of accidents and injuries that may occur when handling sharp tools and heavy machinery.

Moreover, CNC machines are equipped with safety features such as sensors and emergency stops to prevent any potential hazards. These sensors can detect any malfunctions or errors in the system, which would then trigger the emergency stop, shutting down the machine and preventing any injuries.

9.Can wolfram steel cnc milling cutter be used for mass production?

Yes, CNC machining is commonly used for mass production as it can produce consistent and high-quality parts at a faster rate compared to traditional manufacturing methods.

10.How precise is wolfram steel cnc milling cutter?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. CNC machining is known for its high precision and accuracy. The level of precision can vary depending on the specific machine, tooling, and materials used, but in general, CNC machining can achieve tolerances as tight as 0.001 inches (0.0254 mm). This level of precision is much higher than what can be achieved through manual machining methods. Additionally, CNC machines can consistently produce parts with the same level of precision, making them ideal for high-volume production.

11.How is the cutting speed controlled in wolfram steel cnc milling cutter?

We focus on innovation and continuous improvement to maintain a competitive advantage.

The cutting speed in CNC machining is controlled by adjusting the spindle speed and the feed rate. The spindle speed refers to the rotational speed of the cutting tool, while the feed rate refers to the speed at which the cutting tool moves along the workpiece. Both of these parameters can be programmed and controlled by the CNC machine's computer software. The operator can input the desired cutting speed into the program, and the machine will automatically adjust the spindle speed and feed rate accordingly. Additionally, the type of cutting tool and the material being machined also play a role in determining the optimal cutting speed.

12.How does wolfram steel cnc milling cutter handle tight tolerances?

We have the leading technology and innovation capabilities, and attach importance to employee training and development, and provide promotion opportunities.

Here are the ways in which CNC machining can handle tight tolerances:

1. Accurate Programming: CNC machines are programmed using computer-aided design (CAD) software, which allows for precise and accurate design specifications. This ensures that the machine cuts the material to the exact dimensions specified in the design.

2. High Precision Tools: CNC machines use high precision cutting tools, such as drills, mills, and lathes, which are capable of cutting materials with high accuracy. These tools are also regularly calibrated to maintain their accuracy.

3. Automated Processes: CNC machines are fully automated, which eliminates the potential for human error. This ensures that the machining process is consistent and precise, resulting in tight tolerances.

4. Advanced Control Systems: CNC machines are equipped with advanced control systems that monitor and adjust the cutting process in real-time. This allows for adjustments to be made to the cutting speed, feed rate, and tool path to ensure tight tolerances are maintained.

5. Quality Control Measures: CNC machining also involves quality control measures, such as using precision measuring tools and performing inspections throughout the manufacturing process. This ensures that the final product meets the specified tolerances.

13.How does wolfram steel cnc milling cutter improve production efficiency?

We actively participate in the wolfram steel cnc milling cutter industry associations and organization activities. The corporate social responsibility performed well, and the focus of brand building and promotion

This technology has greatly improved production efficiency in many industries. Firstly, CNC machines are able to run continuously without human intervention. This means that production can continue 24/7, leading to a significant increase in output. Additionally, CNC machines are highly precise and can produce complex parts with tight tolerances, resulting in less waste and higher quality products. Because the computer programming controls the entire process, there is also less room for error, leading to a decrease in defects and rework. Finally, through the use of advanced software and tools, CNC machining allows for faster production cycle times, reducing overall lead times and improving overall productivity. Overall, CNC machining plays a vital role in improving productivity, reducing costs, and increasing the competitiveness of businesses in today's fast-paced market.

14.What type of finishes can be created with wolfram steel cnc milling cutter?

Our mission is to provide customers with the best solutions for wolfram steel cnc milling cutter.

CNC machining is a versatile manufacturing process that uses computer-controlled tools to create precise and intricate finishes on a wide range of materials. It is capable of producing a variety of finishes, including smooth, glossy, matte, textured, and even 3D designs. CNC machining can accurately replicate any design, making it ideal for producing high-quality and consistent finishes on products such as metal components, plastic parts, and wood objects. The process allows for intricate details and precise dimensions to be achieved, providing endless possibilities for creating unique and customized finishes for various industries, from automotive and aerospace to fashion and furniture.

15.What file formats are compatible with wolfram steel cnc milling cutter?

Common file formats used in CNC machining include STEP, IGES, and STL for 3D designs, and DWG, DXF, and PDF for 2D drawings.

Our Headquarters

6/F,Tiankaisheng Business Building, Building 46th.,No. 25th Quater,Gongming Str., Guangming, Shenzhen,ChinaLearn More