1 24 scale aluminum wheels cnc files

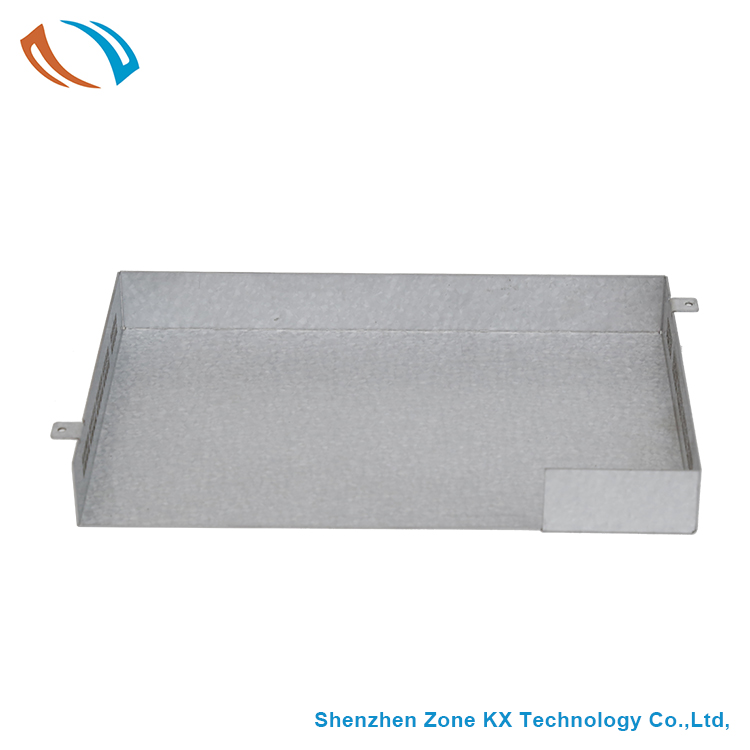

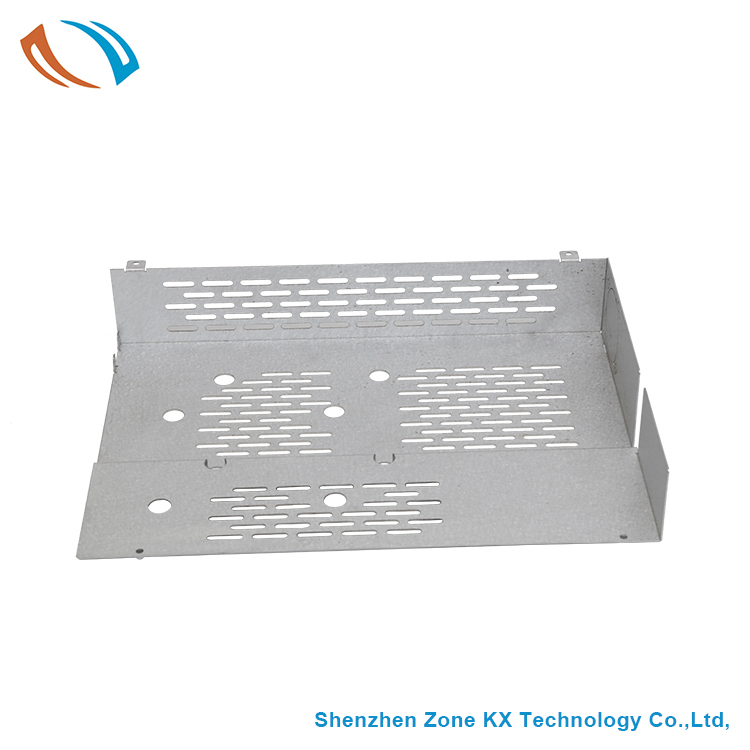

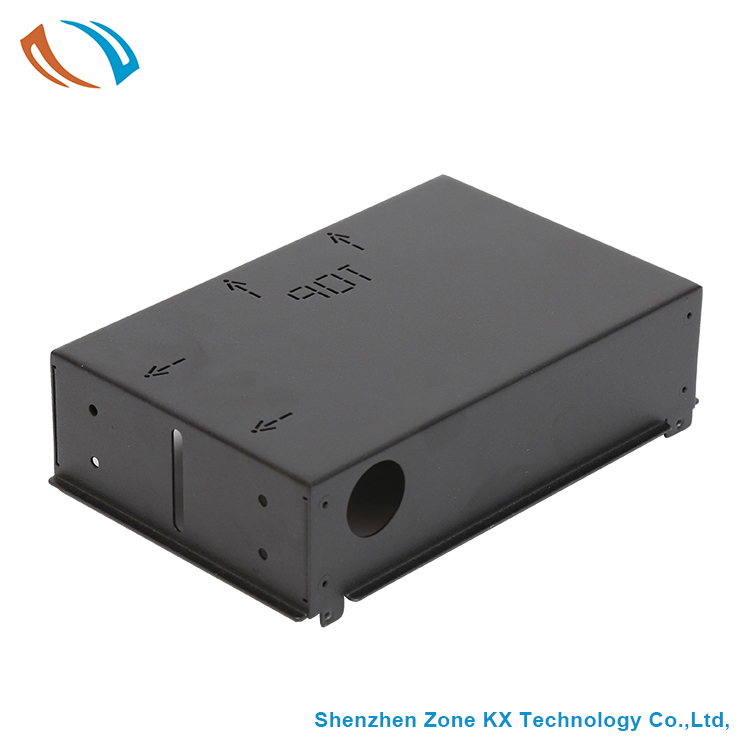

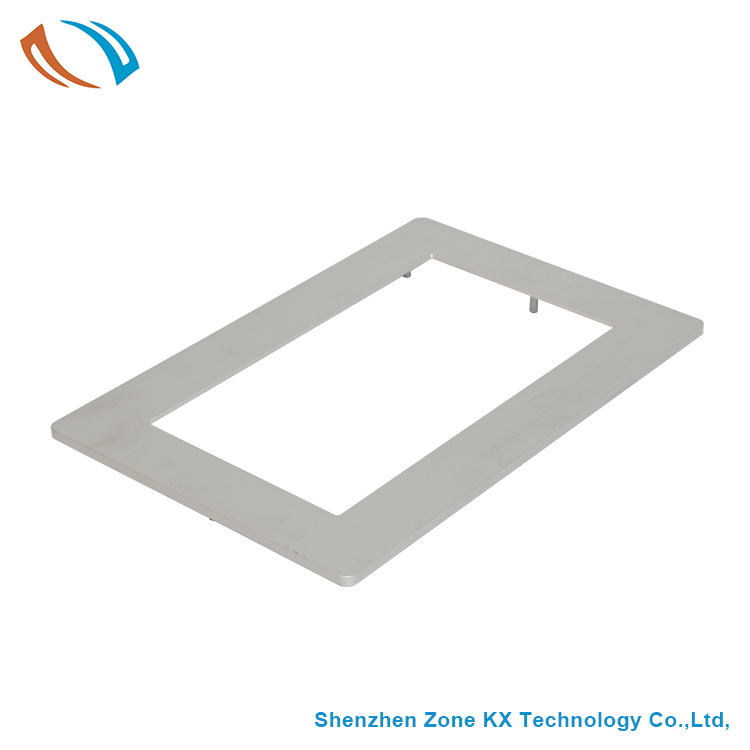

Product Name: CNC Machining ProductProduct Type: Mechanical Component

Production Materials: Various Metals (Aluminum, Steel, Titanium, etc.)

Production Process: CNC Machining

Dimension Tolerance: +/- 0.01mm

Surface Finish: Smooth (Ra < 0.8um)

Product Strength: High

Product Accuracy: Precise

Production Capacity: Customized according to customer requirements

Lead Time: Variable, depending on product complexity and quantity

Quality Control: Strict inspection and measurement of every product

Application: Widely used in aerospace, automotive, electronics, and other industries

Advantages: High precision, complex shapes achievable, efficient production, cost-effective

Special Requirements: Customized surface treatment, specific material selection, tight tolerances, etc.

The cornerstone of ZONE-KX Technology's success is customer service at every step of the pre-sales and after-sales process. We work closely with our customers first to identify their exact needs during the design process and commit to planning to prevent costly errors and delays during manufacturing and after delivery. Our skilled staff will strive to thoroughly understand your requirements. Our skills, knowledge, and rich experience are dedicated to meeting your needs, making our customers feel that Chuanghe is not only a supplier, but also a partner.

| Place of Origin | Guangdong, China |

| CNC Machining or Not | Cnc Machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, Other |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Micro Machining or Not | Micro Machining |

| Brand Name | ZONE-KX Technology |

| Product name | Customized metal Parts |

| Keyword | 1 24 scale aluminum wheels cnc files |

| Process | CNC Milling/Turning |

| Surface treatment | Color Anodize/Sandblasting |

| Service | Customized OEM |

| Materials Avaliable | aluminum/Brass/Stainless Steel/POM(delrin) etc., |

| Tolerance | High Precision Customized |

| Drawing Format | PDF, STEP, IGS, DWG |

| Certification | ISO/Verified factory Supplier |

| Quality control | 100% inspection |

| Packaging Details | packaging special for export carton or wooden box |

| Supply Ability | 233409 Piece/Pieces per Month |

| Quantity (pieces) | > 44159 |

| Lead time (days) | 21 |

1 24 scale aluminum wheels cnc files bearings FAQs Guide 1 24 scale aluminum wheels cnc files offers a wide range of capabilities, including milling, turning, drilling, and grinding, to produce parts with tight tolerances, intricate designs, and smooth surface finishes. This process is used in a variety of industries, including automotive, aerospace, medical, and electronics, to create high-quality components for everything from engine parts to surgical instruments.

2.What is the role of programming software in 1 24 scale aluminum wheels cnc files?

3.Does 1 24 scale aluminum wheels cnc files require specialized tools?

4.How does 1 24 scale aluminum wheels cnc files work?

5.Can 1 24 scale aluminum wheels cnc files be done on curved or irregularly shaped surfaces?

6.How does 1 24 scale aluminum wheels cnc files ensure the safety of the operator?

7.Are there any recycling options for materials used in 1 24 scale aluminum wheels cnc files?

8.What is the cost of 1 24 scale aluminum wheels cnc files compared to other manufacturing methods?

9.What file formats are compatible with 1 24 scale aluminum wheels cnc files?

10.Is 1 24 scale aluminum wheels cnc files environmentally friendly?

11.How do I choose the right CNC machine for my project?

12.Is 1 24 scale aluminum wheels cnc files suitable for rapid prototyping?

13.How does the cost of 1 24 scale aluminum wheels cnc files compare to traditional machining methods?

14.Can intricate and complex designs be manufactured using 1 24 scale aluminum wheels cnc files?

15.What is the difference between 2D and 3D designs in 1 24 scale aluminum wheels cnc files?

16.What type of finishes can be created with 1 24 scale aluminum wheels cnc files?

1.What types of tools are used in 1 24 scale aluminum wheels cnc files?

We operate our 1 24 scale aluminum wheels cnc files business with integrity and honesty.

1. CNC Machines: These are the main tools used in CNC machining. They are computer-controlled machines that can perform a variety of operations such as cutting, drilling, milling, and turning.

2. Cutting Tools: These include drills, end mills, reamers, and other tools used to remove material from the workpiece.

3. Lathe Tools: These are used in lathe machines to shape and cut the workpiece.

4. Milling Tools: These include milling cutters, face mills, and other tools used to remove material from the workpiece in a milling machine.

5. Drilling Tools: These include drill bits, countersinks, and other tools used to create holes in the workpiece.

6. Grinding Tools: These include grinding wheels, abrasive belts, and other tools used to smooth and finish the surface of the workpiece.

7. Boring Tools: These are used to enlarge or shape existing holes in the workpiece.

8. EDM Tools: These include electrodes, wire, and other tools used in electrical discharge machining to cut and shape the workpiece.

9. Inspection Tools: These include calipers, micrometers, and other measuring tools used to ensure accuracy and precision in the machining process.

10. Software: CNC machining also requires specialized software to program and control the machines, such as CAD/CAM software.

2.What is the role of programming software in 1 24 scale aluminum wheels cnc files?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously.

Some of the key functions of programming software in CNC machining include:

1. Creating and editing toolpaths: Programming software allows users to create and edit toolpaths, which are the specific paths that the cutting tool will follow to create the desired shape or design.

2. Defining cutting parameters: The software also allows users to specify the cutting parameters such as speed, feed rate, and depth of cut, which are essential for achieving the desired results.

3. Simulating and optimizing programs: Before running the program on the actual machine, the software allows users to simulate and optimize the program to identify any potential issues or errors.

4. Generating G-code: G-code is the language that CNC machines understand, and programming software is responsible for generating this code based on the user's instructions.

5. Managing multiple axes: CNC machines can have multiple axes of movement, and programming software allows users to control and coordinate these axes to create complex shapes and designs.

6. Integrating with CAD/CAM software: Programming software can also integrate with CAD/CAM software, allowing users to directly import designs and models into the program for easier programming.

3.Does 1 24 scale aluminum wheels cnc files require specialized tools?

Yes, CNC machining requires specialized tools such as CNC machines, cutting tools, measuring instruments, and computer software. These tools are specifically designed and calibrated for precision and accuracy in the CNC machining process.

4.How does 1 24 scale aluminum wheels cnc files work?

CNC machines use computer-aided design (CAD) and computer-aided manufacturing (CAM) software to guide the cutting tools and move the workpiece, which is held in place by a vice or clamp, in a precise and programmed manner.

5.Can 1 24 scale aluminum wheels cnc files be done on curved or irregularly shaped surfaces?

Yes, CNC machining can be done on curved or irregularly shaped surfaces. CNC machines use computer programming and advanced tooling to precisely cut and shape materials. The machine is able to follow complex and irregular curves by using specialized software to convert the design into a series of movement instructions for the machine's cutting tools. This allows for intricate and accurate machining on curved or irregularly shaped surfaces.

6.How does 1 24 scale aluminum wheels cnc files ensure the safety of the operator?

CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-controlled machines to produce high-precision parts and components. This technology has revolutionized the manufacturing industry by increasing productivity and efficiency. Apart from its benefits in terms of production, CNC machining also prioritizes the safety of the operator.

One way CNC machining ensures the safety of the operator is by eliminating the need for direct contact with cutting tools. The entire process is automated, and the operator only needs to input the design and specifications into the computer. This removes the risk of accidents and injuries that may occur when handling sharp tools and heavy machinery.

Moreover, CNC machines are equipped with safety features such as sensors and emergency stops to prevent any potential hazards. These sensors can detect any malfunctions or errors in the system, which would then trigger the emergency stop, shutting down the machine and preventing any injuries.

7.Are there any recycling options for materials used in 1 24 scale aluminum wheels cnc files?

Yes, there are several recycling options for materials used in CNC machining, such as aluminum, steel, and plastic. These materials can be melted down and reused for new products or repurposed for other industrial applications. Some CNC machine shops also have their own recycling programs in place to properly dispose of and recycle scrap materials generated during the machining process. Additionally, there are recycling facilities that specialize in handling industrial waste and scrap metals from CNC machining, ensuring that these materials are responsibly processed and reused.

8.What is the cost of 1 24 scale aluminum wheels cnc files compared to other manufacturing methods?

The cost of CNC machining can vary depending on the complexity of the design, material, and production quantity. In general, CNC machining may have a higher initial cost compared to traditional manufacturing methods, but can be more cost-effective in the long run for larger production runs.

9.What file formats are compatible with 1 24 scale aluminum wheels cnc files?

Common file formats used in CNC machining include STEP, IGES, and STL for 3D designs, and DWG, DXF, and PDF for 2D drawings.

10.Is 1 24 scale aluminum wheels cnc files environmentally friendly?

CNC machining can be environmentally friendly if sustainable materials are used and if the machining process is optimized to reduce waste. CNC machines also have the ability to recycle and reuse excess material, minimizing the overall environmental impact.

11.How do I choose the right CNC machine for my project?

To choose the right CNC machine, consider the type of material, size and complexity of your design, production requirements, and budget.

12.Is 1 24 scale aluminum wheels cnc files suitable for rapid prototyping?

Yes, CNC machining is a great option for rapid prototyping because of its high precision and the ability to work with a variety of materials.

13.How does the cost of 1 24 scale aluminum wheels cnc files compare to traditional machining methods?

As one of the 1 24 scale aluminum wheels cnc files market leaders, we are known for innovation and reliability.

The cost of CNC machining can vary depending on factors such as the complexity of the part, the material being used, and the quantity being produced. However, in general, CNC machining tends to be more cost-effective than traditional machining methods.

One reason for this is that CNC machines can operate continuously without the need for breaks or rest, resulting in faster production times and lower labor costs. Additionally, CNC machines can produce highly precise and accurate parts, reducing the need for manual adjustments and minimizing material waste.

Traditional machining methods, on the other hand, often require more manual labor and can be slower and less precise, leading to higher labor costs and more material waste. They may also require multiple machines and processes to produce a single part, adding to the overall cost.

Overall, while the initial investment in CNC machines may be higher, the long-term cost savings and efficiency make it a more cost-effective option compared to traditional machining methods.

14.Can intricate and complex designs be manufactured using 1 24 scale aluminum wheels cnc files?

I have a comprehensive after -sales service system, which can pay attention to market trends in time and adjust our strategy in a timely manner. Yes, intricate and complex designs can be manufactured using CNC machining. CNC machining is a highly precise and accurate manufacturing process that uses computer-controlled machines to cut and shape materials into specific designs. This process allows for the creation of intricate and complex designs with high levels of precision and repeatability. With the use of advanced software and tools, CNC machines can produce intricate and complex designs with intricate details and tight tolerances. This makes CNC machining a popular choice for manufacturing parts and components for various industries, including aerospace, automotive, medical, and more.

15.What is the difference between 2D and 3D designs in 1 24 scale aluminum wheels cnc files?

2D designs in CNC machining refer to drawings or blueprints that contain 2-dimensional objects and shapes, such as lines, circles, and squares. These designs are typically used for CNC milling or cutting processes, where the machine moves along the X and Y axes to cut or carve the material.

On the other hand, 3D designs in CNC machining contain information about 3-dimensional objects, including depth and volume. These designs are used for more complex CNC machining processes, such as 3D printing or multi-axis milling, where the machine can move along multiple axes to create intricate and detailed shapes.

16.What type of finishes can be created with 1 24 scale aluminum wheels cnc files?

Our mission is to provide customers with the best solutions for 1 24 scale aluminum wheels cnc files.

CNC machining is a versatile manufacturing process that uses computer-controlled tools to create precise and intricate finishes on a wide range of materials. It is capable of producing a variety of finishes, including smooth, glossy, matte, textured, and even 3D designs. CNC machining can accurately replicate any design, making it ideal for producing high-quality and consistent finishes on products such as metal components, plastic parts, and wood objects. The process allows for intricate details and precise dimensions to be achieved, providing endless possibilities for creating unique and customized finishes for various industries, from automotive and aerospace to fashion and furniture.

Our Headquarters

6/F,Tiankaisheng Business Building, Building 46th.,No. 25th Quater,Gongming Str., Guangming, Shenzhen,ChinaLearn More